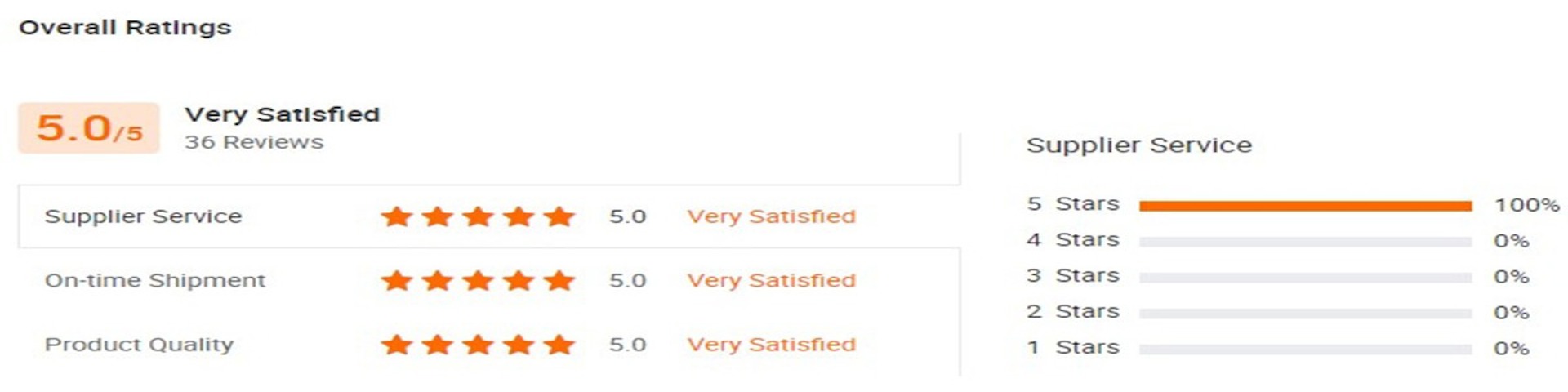

В мире электроники и автоматизации коннекторы играют ключевую роль, обеспечивая надежное соединение между различными компонентами. Одним из самых популярных и эффективных типов являются коннекторы с штыревыми контактами. В этой статье мы подробно разберем, что они из себя представляют, как работают, их преимущества, сферы применения и почему они являются незаменимым инструментом для инженеров, проектировщиков и любителей электроники.

Введение в коннекторы с штыревыми контактами

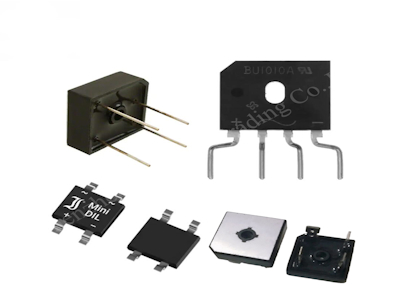

Коннектор с штыревыми контактами – это устройство, предназначенное для создания электрического соединения между двумя или более компонентами. Его основная особенность заключается в использовании штыревых контактов, которые вставляются в соответствующие гнезда или разъемы. Эти коннекторы широко применяются в различных отраслях, от бытовой электроники до промышленной автоматизации, благодаря своей простоте, надежности и универсальности.

История развития коннекторов насчитывает десятилетия. Первые аналоги появились еще в начале XX века, но с развитием технологий они эволюционировали, став более компактными, эффективными и специализированными. Сегодня коннекторы с штыревыми контактами – это результат многолетних инноваций, направленных на улучшение производительности и снижение costs.

В современном мире, где электроника проникла во все сферы жизни, importance of reliable connections cannot be overstated. Whether it's a smartphone, a medical device, or an industrial robot, the quality of connectors directly affects performance, safety, and longevity. That's why understanding and choosing the right connector is crucial for any project.

Принцип работы коннекторов с штыревыми контактами

Принцип работы коннектора с штыревыми контактами основан на простом, но эффективном механизме. Штыревые контакты, обычно изготовленные из проводящих материалов, таких как медь или золото, вставляются в гнезда, которые имеют соответствующие контактные поверхности. При соединении, контакты обеспечивают электрический контакт через физическое соприкосновение, передавая сигналы или питание.

Процесс соединения typically involves several steps. First, the pins are aligned with the sockets. This alignment is critical to avoid damage and ensure a proper connection. Many modern connectors include features like keying or polarization to prevent incorrect insertion. Once aligned, the pins are inserted, often with a slight force, which ensures a tight and secure fit. The contact surfaces are designed to minimize resistance and maximize conductivity.

Materials used in these connectors are chosen for their electrical properties, durability, and corrosion resistance. For example, gold plating is common for high-reliability applications because it provides excellent conductivity and prevents oxidation. The housing of the connector is usually made from insulating materials like plastic or ceramic to prevent short circuits and provide mechanical support.

In terms of electrical performance, connectors must maintain low contact resistance and high insulation resistance. This is achieved through precise manufacturing and quality control. Advanced designs may include features like shielding to reduce electromagnetic interference (EMI), which is essential in sensitive electronic systems.

Преимущества коннекторов с штыревыми контактами

Коннекторы с штыревыми контактами offer numerous advantages that make them a preferred choice in many applications. One of the key benefits is reliability. Thanks to their simple design, they are less prone to failure compared to more complex connectors. The physical contact ensures a stable connection that can withstand vibrations, temperature changes, and other environmental factors.

Another advantage is ease of use. These connectors are designed for quick and easy installation and removal, which is particularly important in fields like maintenance and prototyping. They often feature tool-less assembly, allowing users to connect and disconnect components without specialized equipment.

Versatility is also a strong point. Connectors with pin contacts come in various sizes, configurations, and ratings, making them suitable for a wide range of voltages, currents, and signal types. From low-power data signals to high-power industrial applications, there is a connector designed to meet specific needs.

Cost-effectiveness is another factor. Due to mass production and standardized designs, these connectors are generally affordable, yet they do not compromise on quality. This makes them accessible for both large-scale industrial use and small DIY projects.

Durability and longevity are enhanced by robust materials and designs. Many connectors are rated for thousands of mating cycles, meaning they can be connected and disconnected repeatedly without significant wear. This is crucial in applications where frequent changes are necessary.

Finally, safety features such as locking mechanisms and insulation help prevent accidents like electric shocks or short circuits, ensuring that users can work with confidence.

Сферы применения

Коннекторы с штыревыми контактами find applications in virtually every industry that involves electronics. In consumer electronics, they are used in devices like computers, smartphones, and home appliances to connect internal components such as boards, sensors, and displays.

In the automotive industry, these connectors are essential for wiring harnesses, connecting everything from engine control units to infotainment systems. They must withstand harsh conditions like temperature extremes, vibrations, and moisture, which is why automotive-grade connectors are specially designed for durability.

Industrial automation relies heavily on connectors for machinery, robots, and control systems. Here, reliability is paramount to avoid downtime and ensure smooth operation. Connectors are used to link sensors, actuators, and controllers, facilitating communication and power distribution.

Medical devices use these connectors for critical applications such as patient monitoring equipment, imaging systems, and surgical tools. High reliability and safety are non-negotiable in this field, often requiring connectors with specific certifications.

Telecommunications infrastructure, including data centers and networking equipment, utilizes connectors for high-speed data transmission. Shielding and low signal loss are key considerations here.

Even in aerospace and defense, where conditions are extreme, connectors with pin contacts are used in avionics, satellites, and military hardware, designed to meet rigorous standards for performance and reliability.

Emerging fields like renewable energy (e.g., solar panels and wind turbines) and IoT (Internet of Things) devices also benefit from these connectors, as they enable efficient and scalable connections in distributed systems.

Как выбрать подходящий коннектор

Choosing the right connector with pin contacts depends on several factors. First, consider the electrical requirements: voltage, current, and signal type. For high-power applications, look for connectors with appropriate ratings and materials that can handle the load without overheating.

Environmental conditions are crucial. If the connector will be exposed to moisture, dust, or extreme temperatures, select one with a high IP (Ingress Protection) rating or specific environmental certifications. For example, connectors used outdoors or in industrial settings often have sealed designs.

Mechanical aspects such as size, weight, and mating force should align with your application. In space-constrained designs, compact connectors are preferable. Additionally, consider the number of mating cycles; if frequent connections and disconnections are expected, choose a connector rated for high durability.

Compatibility with existing systems is important. Standardized connectors like those following IEC or MIL specifications ensure interoperability and ease of replacement. However, for custom applications, proprietary designs might be necessary.

Cost is always a consideration, but it should not compromise quality. Balance your budget with the required performance and reliability. Sometimes, investing in a higher-quality connector can save money in the long run by reducing maintenance and downtime.

Lastly, ease of installation and availability of accessories (like cables and tools) can influence your choice. Many manufacturers provide detailed datasheets and support to help you make an informed decision.

Инновации и будущее коннекторов

The field of connectors is continuously evolving, driven by advancements in technology and increasing demands for performance. Recent innovations include miniaturization, with connectors becoming smaller yet more powerful to fit into compact devices like wearables and IoT sensors.

Materials science has led to the development of new alloys and coatings that enhance conductivity and corrosion resistance. For instance, nanotechnology is being explored to create surfaces that maintain low resistance even after many mating cycles.

Smart connectors are emerging, integrating sensors and electronics to monitor connection status, temperature, or other parameters in real-time. This can help predictive maintenance and improve system reliability.

Environmental sustainability is becoming a focus, with manufacturers designing connectors that are recyclable and made from eco-friendly materials. Energy efficiency is also a goal, with designs that minimize power loss.

In the future, we can expect connectors to become even more integrated with wireless technologies, perhaps reducing the need for physical connections in some applications. However, for reliability and security, wired connections will likely remain essential in critical systems.

Standards organizations are working on new specifications to keep pace with technologies like 5G, artificial intelligence, and electric vehicles, ensuring that connectors can handle higher data rates and power demands.

Заключение

Коннекторы с штыревыми контактами – это фундаментальный компонент современной электроники, offering reliability, versatility, and ease of use. Whether you are an engineer, a hobbyist, or a business owner, understanding how they work and how to choose the right one can significantly impact the success of your projects.

By investing in quality connectors, you ensure not only the performance of your devices but also their safety and longevity. As technology advances, these connectors will continue to evolve, providing even better solutions for the connected world of tomorrow.

We hope this article has provided valuable insights. If you have any questions or need assistance in selecting connectors for your specific needs, feel free to reach out to our experts. Together, we can build a more connected and efficient future.

Следующий пост: Почему гибкие печатные платы меняют мир технологий

1388xx888xx

1388xx888xx 1388xx888xx@gmail.com

1388xx888xx@gmail.com